In this factory where the management of the risk of contamination is an essential factor, having a reliable compressed air system is fundamental. This is why the choice of models was guided on Sullair’s reputation for reliability. Following the many reliability problems with other compressors brand, the time had come to acquire reliable machines with flawless operation with unparalleled durability.

Another criteria that helped in the selection of devices with the engineering team was the ability to add options on the compressor. The Sullair configuration menu allows the addition of security requirements, for example. During the RQF (request for quote), the Sullair models already had the options with all the specifications without deviation to tender.

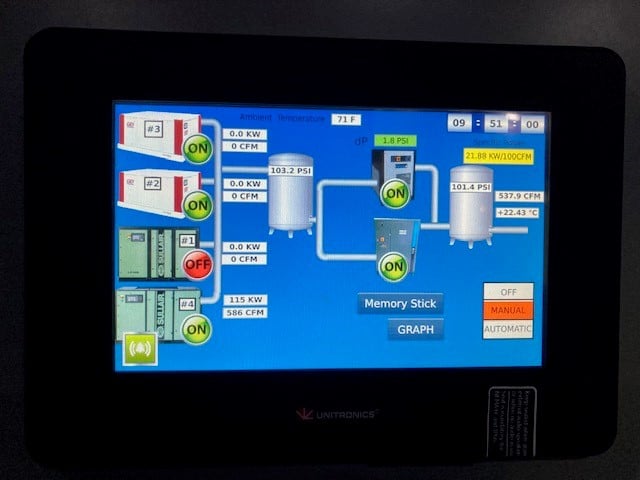

Finally, Sullair’s AirLinx option available on LS-Series compressors, allows remote monitoring, real-time logging of air compressor parameters and observing machine performance through a simple edge and easy to read on a mobile phone or computer. AirLinx also alerts in the event of failures and unscheduled shutdowns. This helps improve system reliability and protect investments. For the engineering team of this manufacturer, the advantages of the AirLinx system were an important asset that they would be able to benefit from to ensure the reliability of the equipment.