During a recent visit to a trade show dedicated to agricultural equipment, our team discovered the full scope of the possible uses for compressed air in the food industry.

During a recent visit to a trade show dedicated to agricultural equipment, our team discovered the full scope of the possible uses for compressed air in the food industry.

First, we observe that agricultural machinery has greatly diversified and the products offered are highly specialized according to crop requirements. Within this equipment, now at the cutting edge of technology, many electronic components incorporated are hidden from view.

Included in these tech savy machines, there are very small pulleys, fragile sensors, electronic wire sheaths and a multitude of tiny components that are critical to the operation of the machine. These large pieces of equipment need to be cleaned regularly to ensure that they work properly. Thorough washing is also necessary when the farmer switches from standard production to cultivation in an organic field; no trace of the regular harvest can mix with its organic production, otherwise it will lose its organic certification! Cleaning the machinery between the different cultures is therefore a crucial step.

In the past, washing with a water-based pressure washer was the established norm. However, this type of rinsing is very harmful to small fragile electronic components. For this reason, more and more producers are turning to air cleaning, which avoids any moisture problems in the wire sheaths which is gentler on the components. Respiratory protective equipment is recommended depending on where the work is being done. All those who have replaced water washing with air cleaning are fully satisfied with the results with no down sides using this process.

Secondly, we were able to observe the use of compressed air in the cleaning of pipes for the spreading of slurry. When tractors spread slurry, they must empty and clean the hoses used once the operation is complete. To do this, large balls of foam are inserted into the pipes that can be up to 5KM long. These balls will rub against the walls of the pipes and thus clean them of all their content. We imagine that it takes great force to push the foam ball several KM into a partially clogged pipe. A properly designed compressed air system is used to accomplish this process.

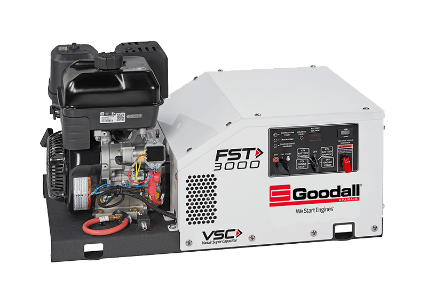

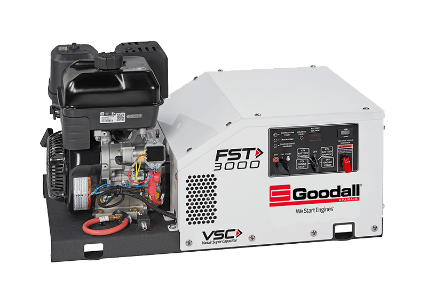

If the fields are far from the main building, farmers will often turn to PTO-type compressors (Power Take Off), i.e. compressors powered by a truck transmission. The Vanair series offers many models and some can be installed directly on the tractor. These models, designed for trucks, need minor modifications in order to work on a tractor. Several companies offer accessories to carry out these small modifications. A great alternative for jobs where electric power is not possible. The Vanair company offers the DR-500 series as well as the AirNArc combo model compressor & welder. Above Deck series hydraulic Vanair units are also used in the agricultural industry.

The compressed air supply is connected to the tractor and its spreading system, the pressure will be adjusted according to the size of the pipe to be cleaned and it is the pressure of the compressed air which will push the balloon through to the end of the pipe. The ball will come out with great velocity and look like a soccer ball when it comes out! However, impossible to catch it; this force is like a cannonball when it comes out!

Field work also requires compressed air for several other functions. For big jobs, portable diesel compressors from Sullair are a trusted brand to use. Some of the more common models are the 185, 375 and 900 models. The number designates the amount of flow in cfm (cubic feet per minute)

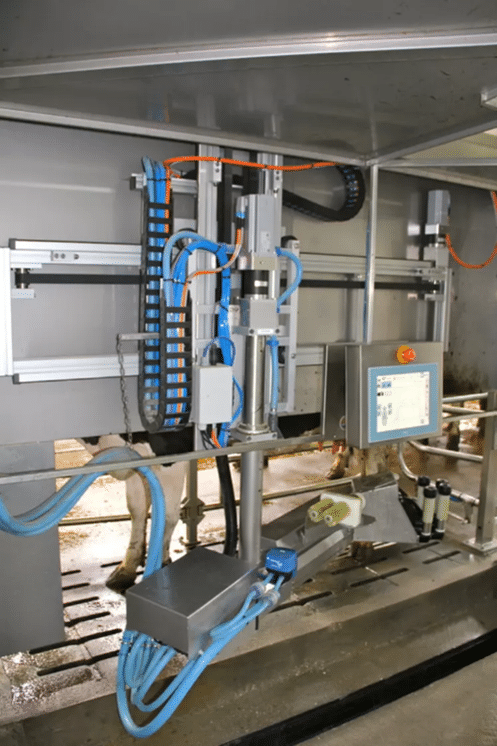

Thirdly, as the entire industry is modernizing, we see more and more machinery arriving on the market that has specific roles in order to optimize agricultural production. One that comes to mind is the robot milkers for dairy cows. Depending on the type of operation, either a robot moves from one cow to another to milk them or the animals are free in a pen and they present themselves to be milked when they feel the need. These highly sophisticated machines recognize cows, adapt the milking machine according to their physical characteristics, calculate the volume of milk harvested, perform analyzes of the quality of milk harvested and finally reward the animal by means of the distribution of “treat” food. Cows that are milked this way will produce on average 15% more milk than a traditional farm. This is quite a process improvement for the producer. Keep in mind whenever the topic of electronic robot is discussed compressed air is a vital operational component. It is a standard requirement to have a solid compressed air network combined with a compressor (with or without oil, depending on production requirements) in place at these large farms in order to support these machines which simplify the life of milk producers.

The most common models found on dairy farms will be Sullair’s encapsulated rotary screw models ES6 and Sullair’s oil-free scroll SRL models. Some reciprocating compressors are also required for small projects.

After this visit to the agricultural show, we realized that compressed air is omnipresent in many facets of modern agriculture. If you are new to this industry, do not hesitate to tell us about your projects, the Comairco team will be able to offer you the compressed air system you need, whether it is powered by electricity or truck/tractor(fuel) and whether the operation requires lubricated or oil free air compressors. For all your compressed air and nitrogen needs in agriculture, Comairco has many solutions to discuss with you!

COMAIRCO offers an emergency compressed air maintenance and compressors maintenance service, 24 hours a day, 7 days a week. Our technicians are available around the clock to perform compressed air installation and compressors installation or repairs.

Find out more